With Dornbracht ReCrafted, we take the principle of the circular economy a step further. Because we regard our products as unique items that are worth preserving. For years now, we have been reconditioning used fittings on behalf of customers as part of our x-tra service and giving them a new lease of life. What the process looks like in detail, so that they leave our production "like new", we show here.

The ReCrafted process in detail

We recondition used bathroom fittings and extend their life cycle. The precise reconditioning of existing components, the integration of new original functional elements, and the high-quality refinement of surfaces are all part of the ReCrafted process. Gentle dismantling and transport are part of the concept, as is quality assurance right from the choice of source material.

-

1. Disassembly

Trained eye: We sift through and evaluate the individual parts

In the first step, the reclaimed fittings are dismantled into individual parts, sifted and evaluated. The components are either remanufactured in the ReCrafted process or, for example if they are wearing parts, separated by type and fed into the recycling circuit at a regional partner. -

2. Decoating

Recovery: Valuable raw materials are preserved

The ReCrafted components are mounted on electroplating racks and the valuable surface raw materials are recovered in an electrolytic process. -

3. Grinding, polishing, brushing

Manual work: the surface is prepared with craftsmanship

Small surface defects are first removed from the ReCrafted workpiece by hand. For shiny surfaces, the metal body is polished. For brushed surfaces, the brush stroke is applied in a precisely defined direction. -

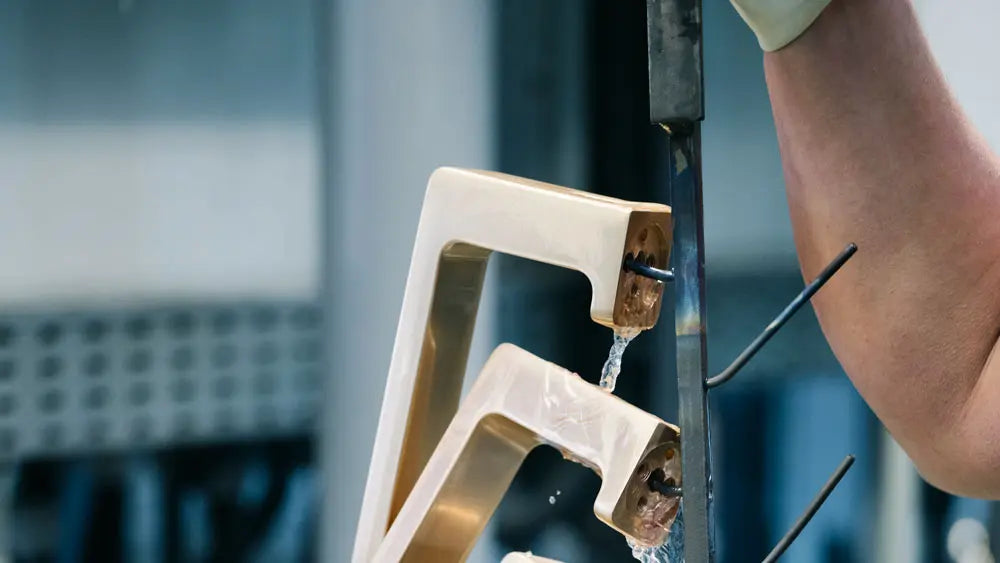

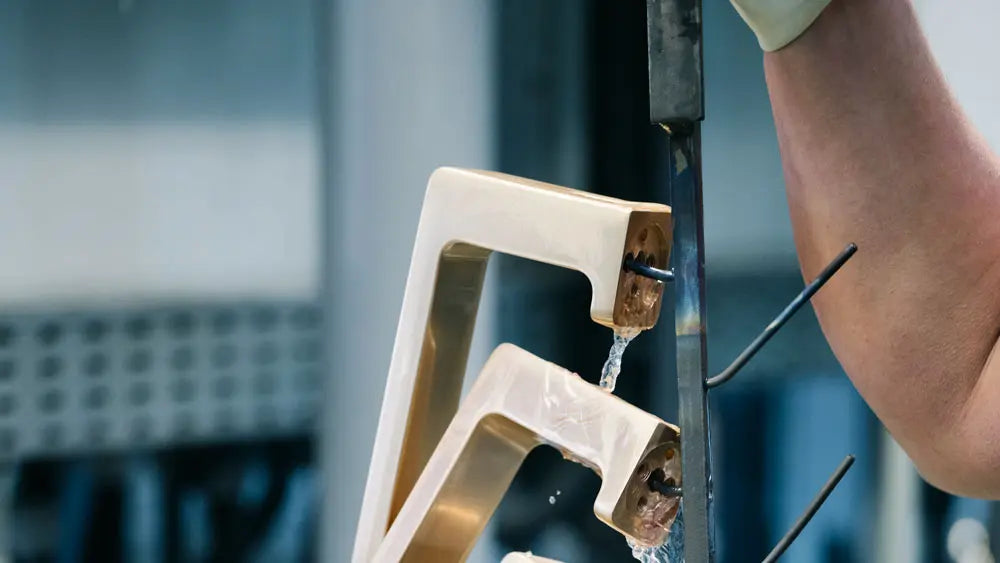

4. Manual surface finishing

Newly refined: From raw body to precious metal

Surface refinement is carried out by hand in our electroplating shop. In the process, high-quality, metallic surfaces are applied. -

5. Laser marking

Unmistakable: every product is marked

The remanufactured product is unmistakably marked as a Dornbracht ReCrafted original by laser. -

6. Commissioning

Like new: Functional parts are completed brand new

During commissioning, the required components are completed, with new functional parts such as mixer cartridges, seals and jet regulators being added. -

7. Assembly and packing

Ecologically packaged: certified brand quality

In the final step, assembly, a leakage and quality test is carried out, among other things, before the Dornbracht ReCrafted product is packed with a certificate in an ecological shipping carton.